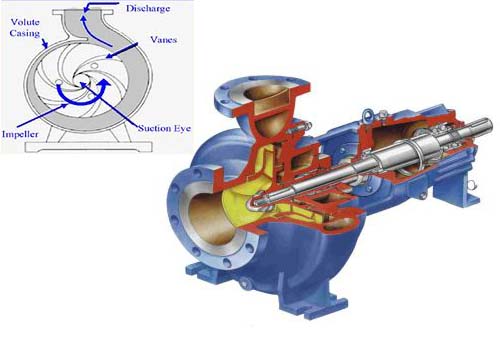

The pump casing provides a pressure boundary for the pump and contains

channels to properly direct the suction and discharge flow.

The pump casing has suction and

discharge penetrations for the main flow path of the pump and normally has small

rain and vent fittings to remove gases trapped in the pump casing or to drain the pump casing for maintenance.

rain and vent fittings to remove gases trapped in the pump casing or to drain the pump casing for maintenance.

|

| centrifugal pump |

Centrifugal pumps can also be constructed in a manner that results in two distinct volutes, each

receiving the liquid that is discharged from a 180o

region of the impeller at any given time.

Pumps of this type are called double volute pumps (they may also be referred to a split volute

pumps). In some applications the double volute minimizes radial forces imparted to the shaft and

bearings due to imbalances in the pressure around the impeller. A comparison of single and

double volute centrifugal pumps is shown on

0 Comments

please do not any spam link in the comment box