|

More than 60% bearing failures are due to lubrication and the Centralized Lubrication systems plays a major role to deliver the grease at

Right Quantity

Right Interval

Right Pressure, which ensures optimized grease quantity is pumped to the bearings to achieve long service life.

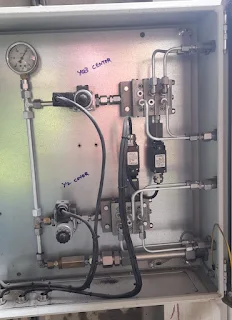

Recently while inspecting a lubrication system supplied by Bijur Delimon for a heavy load application, I noticed a 2/2 electrically operated solenoid valve is used before the progressive distributor to hold grease pressure of 150bar for more than 30 minutes under pressure.

Bearings always have internal clearance and space for grease with very minimum back pressure which will allow grease to enter in less than 10-20 bar pressure, then why 150bar grease pressure is maintained for 30 minutes?

Will oil separation occur when grease at 150bar pressure is

locked for 30 minutes and later released into the bearings?

Lubrication systems are LOW pressure and not high pressure like hydraulics, then why 150bar pressure is applied on grease for 30 minutes?

Can we ensure the same grease quality from barrel to bearings after 150bar static pressure applied for 30 minutes?

Will static oil separation occur at 150bar pressure applied on grease for 30 minutes?

Let's see if any experts have some interesting comments please

0 Comments

please do not any spam link in the comment box